The workflow

Embracing an OPEN 3D workflow

Scan & Measure

Scan, Measure anywhere, anytime, in a matter of seconds

You want :

- Capture easily 3D models of your patient’s anatomy

- Streamline your measurements workflow

- Reduce the cost of deployment to your practitioners network

- Improve practitioner’s adoption of your digital processes

Solutions :

FootScan3D mobile app and our 3D scanners portfolio empowers your field practitioners to:

- Be truly mobile between clinics and remote consultations with a mobile scan app at their fingertips.

- Offer easy to use scanning options adapted to your practitioners measurement’s habits

- Digitize the foambox /cast process to save on productivity, logistics and turnaroud time.

In the world of O&P, precision and replicability are paramount. Traditional manual methods, while foundational, often consume significant time and can be subject to variability between sessions or clinicians.

By leveraging 3D scanning techniques, we not only ensure accurate measurements and alignments within seconds, but also guarantee consistency and replicability across multiple scans or patient visits.

This uniformity becomes crucial for longitudinal patient care. As we engage with patients daily, this blend of speed, precision, and reliability translates to improved customization and optimal therapeutic outcomes

Align & Rectify

Align, rectify your scan in a clinically relevant way and implement your measurements in a few clicks

You want :

- Transmit clear & error free alignement and rectification instructions to your lab's teams;

- Accept work orders even if the quality of the scan is questionable;

- Facilitate your designer’s efforts in decrypting clinician’s prescriptions.

Solutions :

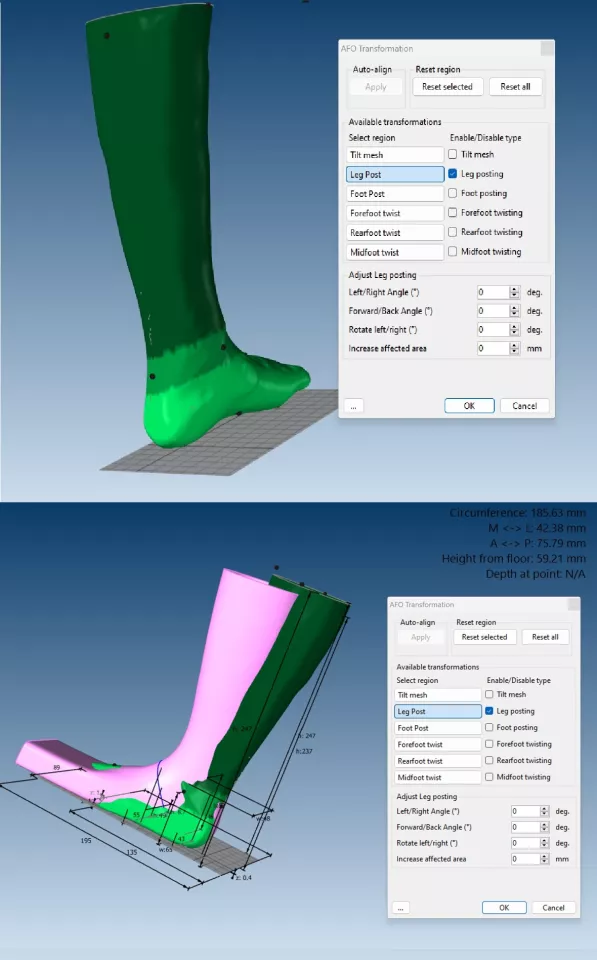

FootCAD3D - Align & Rectify toolbox empowers clinicians or designers to :

- Digitize the cast and plaster workload to boost clinician‘s productivity;

- Let clinicians define visually or quantitatively proper alignments and rectifications;

- Improve mutual understanding on expected outcomes for the design work;

- Reduce design errors downstream and the overall turnaroud time.

FootCAD3D Align & Rectify toolbox enables visual realignment of articulations using landmarks at the simplicity of your mouse.

The system corrects alignment based on your expert decisions, even if initial scans are imperfect.

It automatically fixes flaws, offering both global and localized model smoothing, ensuring a reliable, high-quality outputs.

For practitioners and/or designers

Design & Solidify

Intuitively design custom FO and lower extremity orthoses with clinical logic

You want :

- Design efficiently clinically relevant custom FO & AFO

- Use production technologies and materials of your choice

- Leverage and future proof your investment in production technology and people

- Keep pace with competition and lead with the ongoing innovation

Solutions :

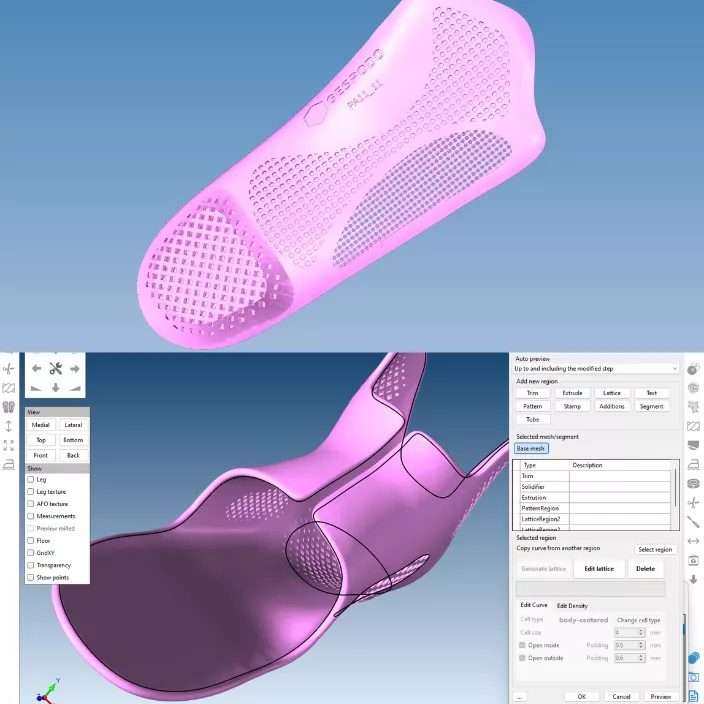

Gespodo FootCAD3D - Design & Solidify tools empowers designers to

- Create, iterate, and optimise your FO & AFO portfolio

- Build your own custom automated worflow for your products

- Save massive amount of time designing, even complex projects at scale

- Open up to innovative fabrication options combining processes and materials

Video FO (Hard shells) - printed MJF/SLS PA11

FootCAD3D clinician-centric 3D Design toolbox, seamlessly merges your clinical insights with advanced 3D design capabilities.

Capitalizing on the strengths of Design for Additive Manufacturing (DfAM), it ensures precise, cost-effective, durable custom orthoses designs.

This digital evolution empowers practitioners to enhance patient care standards, balancing unparalleled precision, creativity and new product development options with economic efficiency

Carve & Print

Carve & Print : Optimize, integrate and innovate with Gespodo

You want :

- Leverage your existing production investments, poeple and know-how

- Boost productivity and enable new options for advanced products

- Streamline and automate reproductible and scalable production process

- Enable Central Fab (C-FAB) or Point of Care (PoC-FAB) operational models

Solutions :

Gespodo OPEN3D API - built on non-proprietary industry standards unlocks:

- Recycle & Optimize your legacy machining infrastructure* (Scanner / CNC)

- Connect to any kind of Printing technology and brands (FDM, SLS, MJF)

- Benefit from DfAM and 3D printing expertise to increase your time to market

- Push the boundaries of innovation by co-creating new hybrid workflows

Video : 7-axis carving of blanks (Ortis & Tillges)

* assuming you are using an interoperable system

Harnessing a blend of traditional craftsmanship and cutting-edge technology is pivotal. Gespodo recognizes the need for labs to maximize their existing investments, optimize legacy machinery, and deliver advanced products without compromising on existing knowledge and skills.

Our OPEN3D API stands as a testament to this commitment.

Crafted on non-proprietary industry standards, it offers labs the versatility to integrate with both legacy systems like scanners and CNC machinery and modern printing technologies spanning FDM, SLS, and MJF.

The choice for an open workflow provides strong benefits that will last

Keep ownership and control of your data

Attract & retain next generation of O&P talents

Ensure easier transmission of know how and craft experience

Future Proof your technology investment