Enhance your foot orthotics practice with advanced 3D design & printing technologies...

While new tools require some learning, our Open 3D workflow and tools are designed for user-friendliness, and with proper training, practitioners can quickly become proficient.

Expect to spend a few hours of onboarding with your Gespodo mentor and get to a full professional proficiency in a matter of a few days.

Mastering 3D design for Additive Manufacturing may require more practice and coaching from DfAM experts. Gespodo will be keen to support you in the knowledge transfer phase.

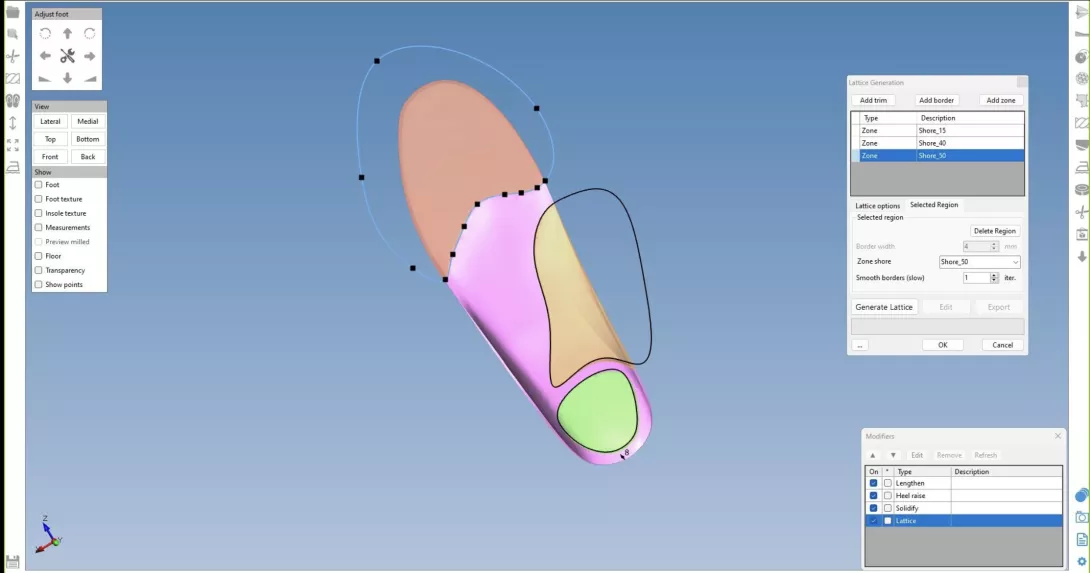

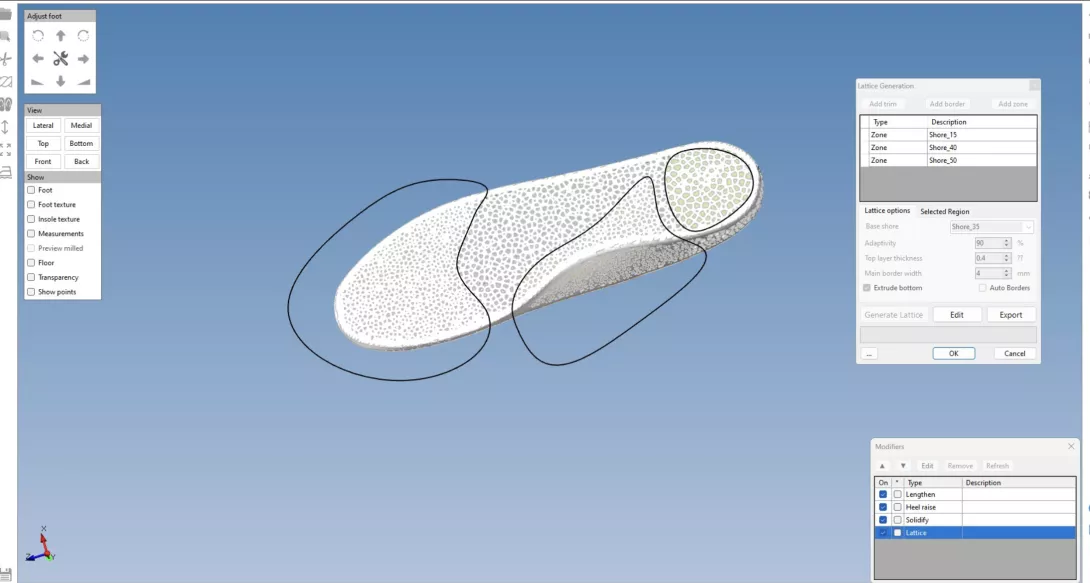

A clinical-centric 3D design solution such FootCAD3D offers enhanced precision and customization, often surpassing traditional methods in terms of fit and biomechanical support.

3D technology enhances the personal touch by allowing more tailored solutions to patient's needs.

But automation doesnt mean loosing the control on your therapeutical choices. It o,nly means an opportunity to freeing up time for more direct and higher quality patient interactions.

3D-designed orthotics are crafted with state-of-the-art materials and techniques, ensuring durability and reliability on par with, if not exceeding, traditional methods.

Looking at the environmental footprint of 3D printed insoles vs traditional or even CNC Milled project, 3D Printing reduced the amount of wasted materials from 80% down to less than 2% per pair.

Investing in 3D technology can initially seem costly, but its efficiency and precision often lead to long-term savings and increased patient satisfaction.

Transitioning can require adjustments, but the enhanced efficiency and capabilities often lead to a more streamlined workflow and enriched team roles.

While 3D production technology and materials evolve quickly, a solid foundation in an open 3D design offers scalability and adaptability, ensuring long-term relevance and return on investment.